How is a high-quality GAC MOTOR made? I guess many car owners have wondered about this. Lean manufacturing in the production line and intelligent manufacturing workshops guarantee the highest quality for GAC MOTOR. With over 550 smart robots and over 1000 sets of automatic systems, the GAC MOTOR factory boasts automatic production, digitization, intelligent management and a manufacturing ecosystem. Intelligent and digitalized management leads to ultra-precision and high efficiency during the car manufacturing and assembling process.

GAC MOTOR’s industry-leading stamping technology features advanced CNC hydraulic die cushion, linear 7-axis robot, 3D simulation technology applied in the entire production line and abrasive tool design, and 100% automation in uncoiling blanking line, laser blank welding and press forming.

With over 400 robots, the welding process is 100% automatic. Thanks to a smart monitoring system, the RFID technology and advanced features including high motor torque, high engine torque, high power, long battery life when running solely on electricity, and low fuel consumption, the welding condition can be recognized automatically and in real time, and welding parameters will be adjusted automatically and accordingly, so as to make sure optimum welding parameters in each welding point, and that each vehicle manufactured is perfectly welded.

During final assembly, using image-based recognition and positioning system, the ABB robots can achieve a repeatability of up to 0.12mm. And the production line adopts fully-automatic and integrated technologies for final assembly.

On the fully-automatic painting line, the 3D image-based recognition system can automatically recognize the information of vehicles and locate installation position, and the spraying robot clamps glasses for painting and installation. The sealant type and painting trajectory are monitored from multiple angles and in real time, and precise positioning and assembly are achieved. The application of smart manufacturing and intelligent detection systems makes sure that vehicles of multiple models can be manufactured simultaneously on the same production line.

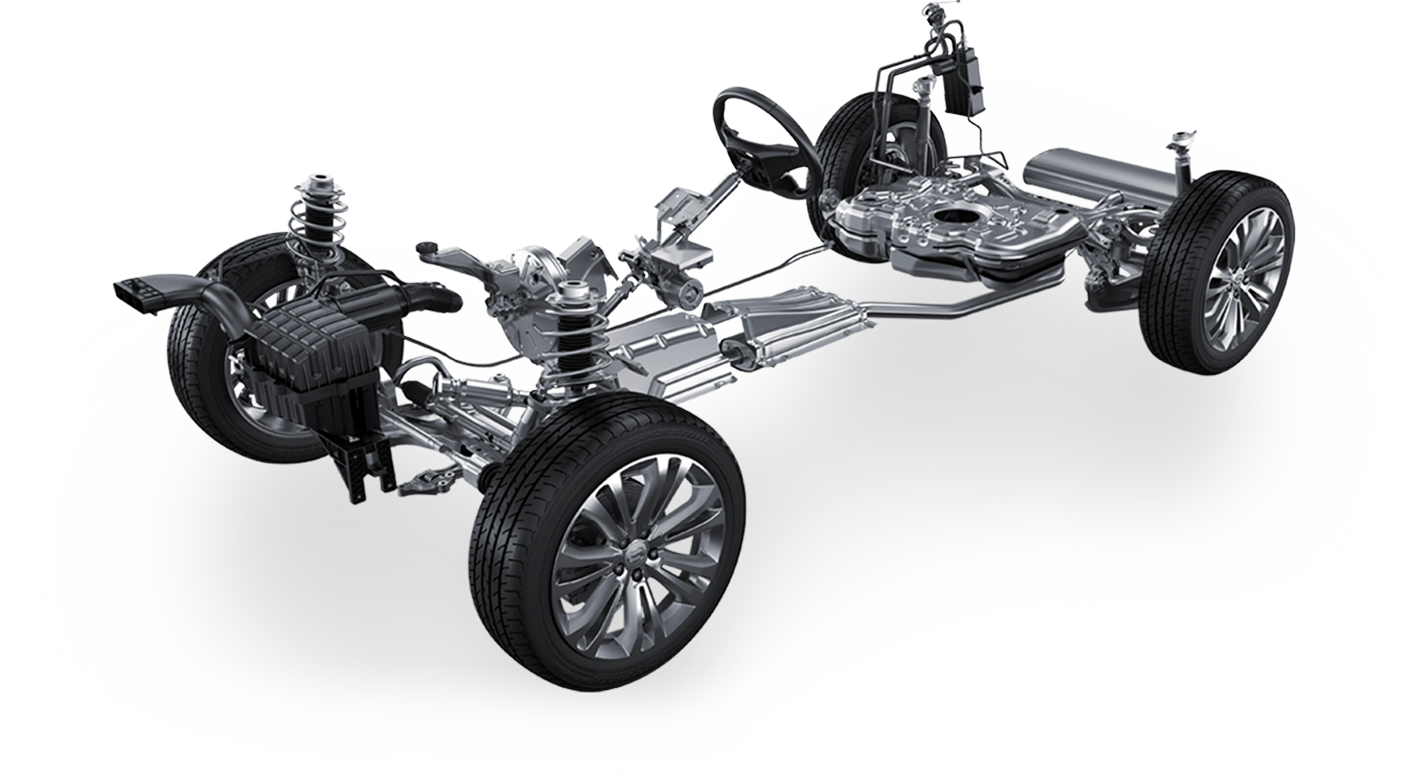

With totally five intelligent robots which enable automatic model recognition, automatic supply of tires and fasteners, and 3D-visual-technology-based automatic tire positioning, as well as the highly intelligent coordination between the tightening system and the assembly robot, more than 20 steps including pre-tightening, forward rotating and angle control can be completed within 10 seconds and precise tightening is achieved.

The whole tire installation system adopts the fault-proof tightening technology to check the tightness of each bolt online and in real time, with the torque accuracy within ±3%. The quality of bolt installation and the safety of the vehicle are guaranteed through intelligent and accurate control, testing and self-adaptive adjustment of torque, delivering safe and pleasant driving experience for every car owner.

The assembly of front seats, automotive interiors, doors, etc., and the filling of liquid coolant, brake fluid, refrigerant, liquid glass cleaner, etc. are completed by two robots.

Equipped with 3D visual tracking system, the robot automatically grips front seats, makes, after visual detection, quick and precise positioning by adjusting seat position from multiple angles, and then automatically putting the seats in place, improving the precision and efficiency during the car manufacturing process.

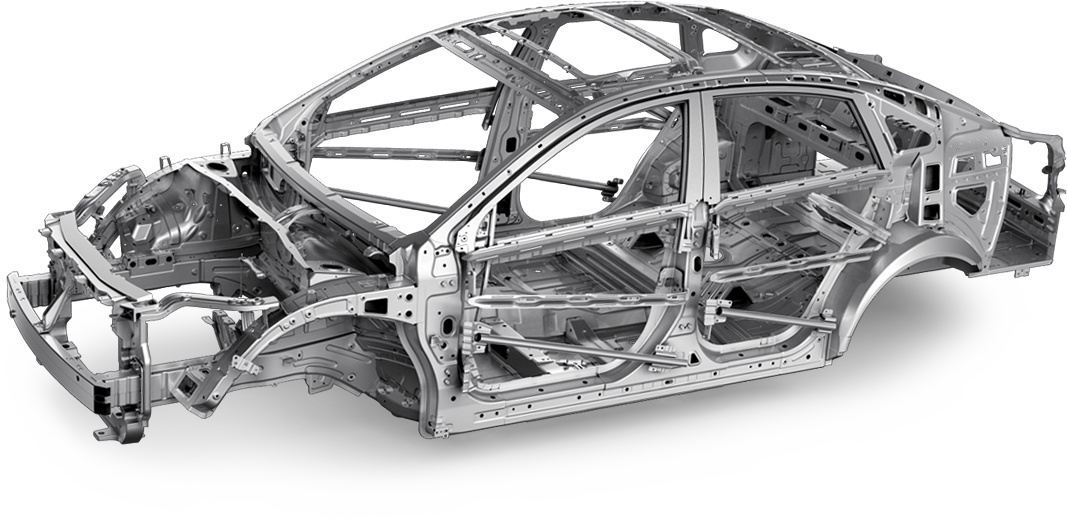

After installing safe, high-strength car body, Bosch and other advanced driving technologies, comfortable seats and anti-viral air filters, the assembly of a GAC MOTOR is completed.

After assembling, GAC MOTOR vehicles need to go through six processes of 42 quality control procedures of more than 3000 inspection or test items, including instrument inspection line, vehicle testing line, comprehensive test track and rainproof line, before they can be sold.

GAC MOTOR boasts a world-leading basic data architecture platform that is able to conduct real-time big data statistical analysis. The whole production line, from body stitching to the torque control of every screw, the quality of each welding point, is controlled in detail in all respects.

Our employees put quality first in all tasks and fields, and create a whole life cycle quality control system with attractive design, safe parts and manufacturing, and heart-warming services.

Every meticulously made vehicle has gone through numerous manufacturing and assembling procedures and more than a thousand detail-oriented inspections and tests, so that they can provide the most comprehensive guarantee for the safety of each and every customer.

GAC MOTOR protects you and your family.